- Home

- About Us

- How we can help you

- Products

- Window & Door Hardware

- Emergency Exit & Panic Hardware

- Window Control Systems

- D-Fine

- Technical Support

- Literature

- FAQs

- News

- Contact Us

There are clear advantages to fitting glass doors: light, visibility, strength and a contemporary aesthetic, but sleek lines can also present a challenge. How can user safety be ensured and finger entrapment prevented when there is no material frame for traditional fitting?

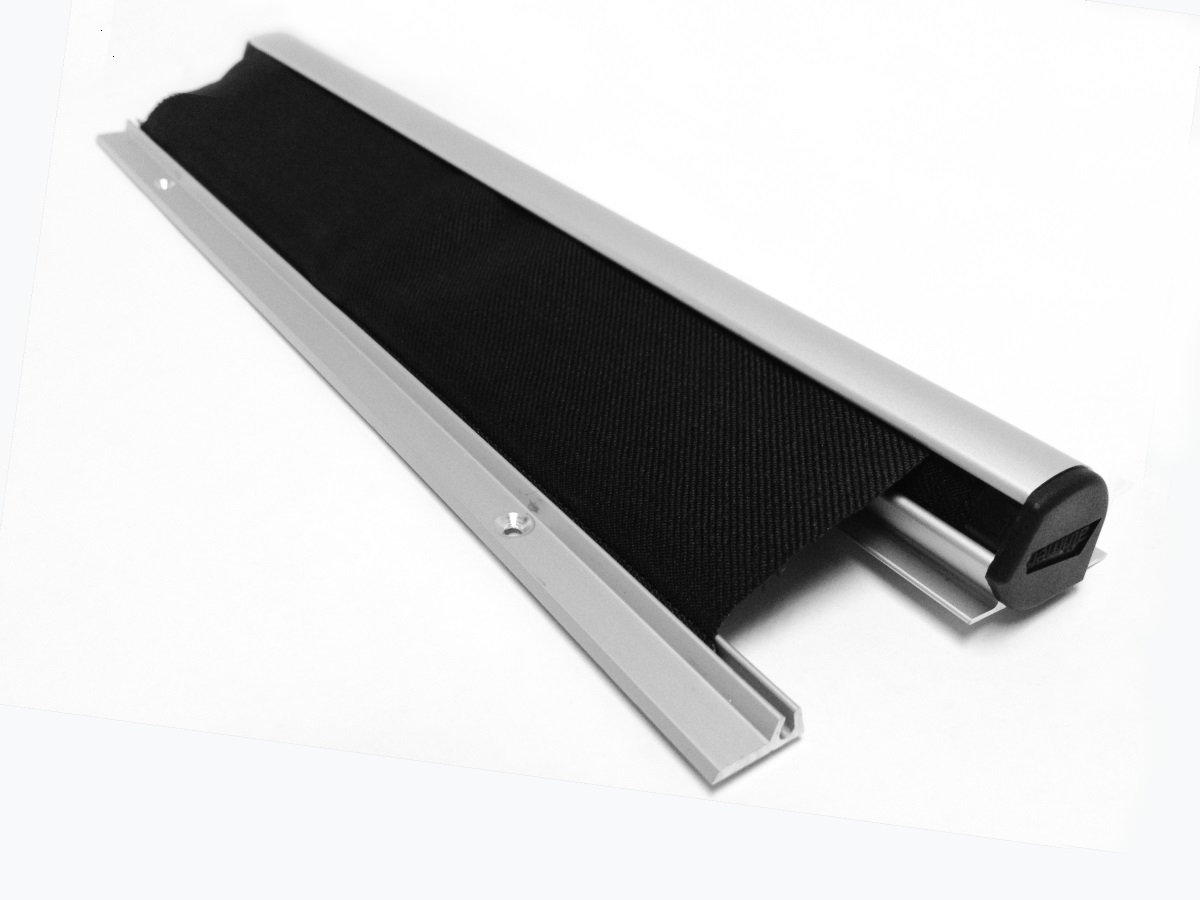

Strand Hardware has the answer – the FP300 finger protection devise. It is purpose made for fitting to glass doors – there’s no drilling necessary as the FP300 is supplied with an acrylate foam high performance tape which bonds the device to the face of the glass door.

It is suitable for internal and external doors, can be retrofitted to new or existing glass doors within a glass frame - single or double action. It is also suitable for fitting to automatic doors.

Said Strand Hardware Sales Director Craig Fox: “The FP300 is the ideal solution to ensure safety without spoiling the glazed aesthetic. The standard finished housing is satin anodised aluminium but can be produced in any RAL powder coated or anodised finish to blend in with the environment.

Standard length is 1925mm but it can also be made to order in any size from 325mm up to a maximum 2500mm.

“As with all our devices within our Athmer finger protection range, it provides an effective barrier to prevent accidental trapping of fingers on the hinge side of the door. In premises used by the public – especially those used by children, the elderly or vulnerable adults - it is essential to minimise risk and finger protection is an essential requirement.”

Risk assessment and identification of appropriate solutions are particularly important for retail establishments, schools, hospitals, care homes and health centres which see a lot of foot traffic.

British and European standards provide specifiers, architects/designers, health and safety professionals and facility managers with guidance as to what works well, what type of devices should be applied to various door sets, what’s durable and essentially, what is safe to use.

Strand Hardware’s finger protection products have been awarded the German Safety Mark and certified to EN16654. The majority have also been tested to BS 8613 and achieved the higher level, class 2. We can also offer longer 2000mm devices which are EN16005 compliant for automatic doors.

The FP300 is cycle tested to 1,000,000 operations and produced using black flame-retardant fabric which can be easily cleaned. The roller has a maximum 260mm fabric travel, making it ideal for wider opening doors. It comes with a two-year warranty.

Selecting the right architectural ironmongery can be a challenge; from the complex and multifaceted requirements of technical specification, to achieving functionality and durability that meet the needs of users within the built environment. Here we outline considerations to steer you to the right choice.

It’s a tough ask: the complexity of selecting the right architectural ironmongery is a process of navigation. There are a range of factors: diverse and seemingly limitless products and variations, project-specific requirements, regulatory compliance, design integration, budget constraints, technological advancements, reliability, and sustainability considerations. Professionals must face these issues, understanding what’s needed to make well-informed decisions which align themselves against the wider ambitions of the project.

The sheer scope of the process can be overwhelming. It is increasingly difficult to compare ‘similar products’ only to find that they are as different as oranges and apples. Seemingly similar products can vary significantly in quality, durability and cost and therefore it’s essential to consider what’s important when preparing your ‘shopping list’.

That being said, there are some things that should never be compromised, safety and security especially – always check that your selected products have been fully tested and meet safety standards. Fit and functionality is also key – finding quality fittings may stretch your budget, especially if they are being purchased towards the end of an expensive development process, but choosing wisely can save money in the long-term and support the overall design aesthetic.

Finding a reliable partner is all important. Working with a trusted supplier is essential because asking the right questions will save you time and direct you to the right solutions. Strand Hardware places great emphasis on its in-house expertise – meaning help is always just a phone call away. Whether you have purchased directly from Strand, or via one of our carefully-selected architectural ironmongers, we will provide you with advice and guidance to make an informed purchase and technical support on installation.

When it comes to products that you can trust, you need look no further than Strand Hardware. As a manufacturer and distributor of specialist architectural ironmongery, our reputation has been built on product quality and durability, alongside outstanding customer service.

We offer a variety of different products across five key ranges: door and windows, emergency exit and panic hardware, window control systems, Glass Central and D-Fine. These incorporate a variety of product types including finger protection, window openers, glass patch fittings and panic hardware made from grade 316 stainless steel.

Although finding the right product to meet functionality, compatibility and suitability for different environs can a difficult task, Strand’s team of experts make this easy. They are on hand to assist with specification queries and if standard products don’t fit the bill, many can be produced in bespoke lengths and finishes.

Among our window and door hardware, is an extensive range of finger protection. These include best-selling FP200 – so good that it comes with a lifetime guarantee (subject to terms and conditions)! There are products to suit most doors: manual and automatic, external and internal, single and double action, including those made from different materials; timber, aluminium, Pvc-u or glass.

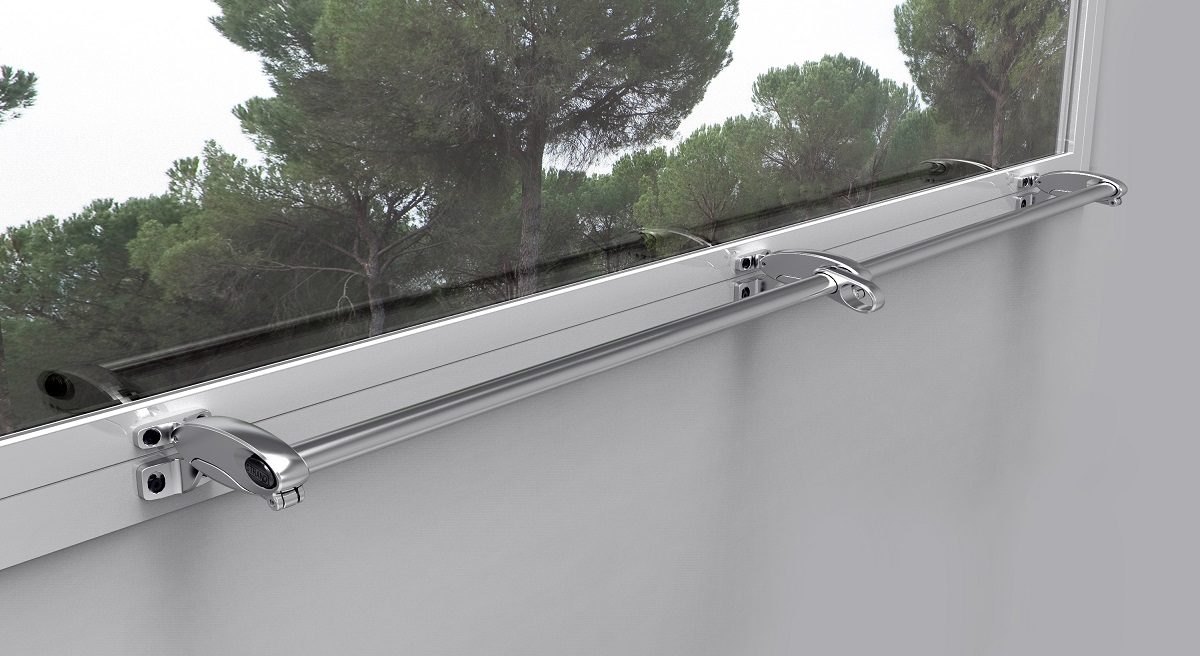

Also included within this parent group, is the Strand Duoflex our range of adjustable folding openers for timber, aluminium, steel and PVCu top hung, outward opening windows. Manufactured in the Midlands they carry the Made In Britain mark, and are available for recessed, flush and stepped profiles, together with a range of accessories.

We are well known for the supply of emergency exit hardware which provides escape devices that combine ease of operation, simplicity of fixing and aesthetic appearance. These come in modular push bar and touch bar options – manual and motorised - together with a range of accompanying products such as outside access devices, strikes and accessories for motorised touch bars.

All our emergency exit and panic hardware products have been rigorously tested and are UKCA and CE marked.

Strand Hardware Window control products are included within our window control systems range. These offer manual and electrically operated natural ventilation solutions which can improve air quality and address potential health and safety risks to better operated high-level or hard to reach windows.

The manual system consists of an opener, fitted to a vent which is linked via lengths of conduit and cable to a wall-mounted operator. It’s a flexible system, as the conduit can be bent around obstructions, with its operating handle positioned at an easily accessible location. There is also an electronic system for a more advanced solution.

Glass Central is Strand’s range of patch fittings for toughened glass walls and doors. This product range has a ‘clear advantage’ and can be used to divide open plan workspaces, providing much-needed privacy space, while maintaining the benefit of natural light sources lost when using other materials to create room separation. Glass Central includes locks, latches, pivots, strike boxes, floor springs, tracks and hinges.

The D-Fine range of panic exit devices is constructed out of grade 316 stainless steel. This guarantees maximum functionality and a long lifetime even under the most extreme weather and atmospheric conditions. They are regularly used on costal buildings, in leisure buildings with swimming pools or environments that suffer extreme weather conditions such as oil rigs.

The range incorporates a variety of push and touch bars – one, two and three point bolt and latch products – and outside access devices. Grade 316 stainless steel is well-established as a corrosion resistant material and all items within the D-Fine range are salt spray tested to 800 hours.

Catalogues featuring each of the ranges can be found in the ‘Literature’ section of this website together with fitting instructions and declarations of performance.

For more information please call our technical sales team on: 01922 639111 or email:

Diverse Product Range:

The sheer diversity of options available in the market can be overwhelming. Professionals need to consider various factors such as functionality, aesthetics, and compatibility with existing structures.

Project-Specific Requirements:

Different projects will have unique requirements based on factors such as building type, usage patterns, security needs, and design preferences. Identifying and aligning the needs of a project with the right solutions requires a nuanced understanding of both the project itself and the capabilities of available products.

Compliance and Regulations:

Building regulations, and standards play a crucial role in the selection of architectural ironmongery. Professionals need to ensure that the chosen hardware meets safety, accessibility, and security standards.

Design Integration:

Architectural ironmongery is not just about functionality; it also contributes significantly to the overall design aesthetics of a space. Selecting hardware that complements the architectural style and design intent of a project is essential. Achieving a harmonious integration while meeting functional requirements can be a delicate balance.

Budget Constraints:

Cost considerations are always a factor in any construction project. Balancing the need for high-quality ironmongery that meets project requirements with budget constraints requires careful evaluation. Cheaper options may compromise on quality and safety.

Technological Advancements:

Architectural ironmongery is constantly evolving. Professionals need to stay updated on the latest innovations and trends to make informed decisions.

Reliability:

Choosing a reliable and reputable supplier is crucial for obtaining high-quality architectural ironmongery. The market is flooded with various suppliers, and ensuring consistency in product quality, delivery timelines, and after-sales support requires thorough vetting.

Sustainability Considerations:

With the increasing focus on sustainability, professionals are now expected to consider the environmental impact of the materials and manufacturing processes used - evaluating the sustainability credentials and outcomes of products.

Good enough to last a lifetime…it’s not often that we hear those words but Strand Hardware is so confident with the quality of it's finger protection that the market leader – it's FP200 - comes with a lifetime guarantee (subject to terms and conditions).

Strand Hardware has been the UK distributor for Athmer finger protection for more than 30 years. It’s the original roller blind finger guard considered by many to be the best.

Why? It’s tried and tested – the jewel in the crown of finger protection which meets bespoke needs including various sizes and finishes. Strand Hardware's extended range features six products that fit most types of doors: manual and automatic, external and internal, single and double action, including those made from different materials; timber, aluminium, Pvc-u or glass.

Finger protection is an essential safety requirement across a variety of environments including public buildings, especially those used by children and vulnerable adults. From hospitality and leisure, to retail, education and health premises, there’s a duty of care to assess risk and apply safety measures to prevent needless accidents.

Definitive statistics on the number of annual finger crush incidents which occur in the UK are difficult to determine. Many go unreported but they contribute to one of the most frequent workplace injuries. It’s also been identified that between 30,000 and 50,000 finger crush incidents per year involve children.

Many require hospital treatment and some result in partial amputation of fingers or permanent nerve damage. Fitting finger guards on the hinge-side of doors prevents fingers being accidentally trapped. Health and safety experts recommend fitting finger protection and door stops to help prevent accidents.

Most of Strand Hardware's roller blind system devices incorporate a strong flame retardant fabric which extends or retracts under tension to cover the gap between the door and the frame. All of it's products have an easy-clean aluminium housing and many are tested to 1,000,000 operations and comply with EN16005, EN16654, BS8613 and the German Safety Mark. Aesthetics are important in any built environment, which is why Strand Hardware's finger protection devices provide the ideal finishing touch.

Most are available in standard finishes - Satin Anodised Aluminium (SAA), White (RAL 9016) or Dark Bronze Anodised (DBA) but other RAL colours and anodised finishes are available as a special to order item. This means that Strand Hardware's finger protection sits in complete harmony with its environment– it doesn’t have to stand out like a sore thumb to prevent one! Most of us will have been through the doors of a popular fast food chain or high street store – companies that have been using them for many years – and probably never noticed them. And yet, they are fixed to entrances and fitting rooms, powder coated to colour match their frames - hidden in plain sight.

Welcome to our first-ever issue of News Strand - the newsletter for Strand Hardware and Strand Technologies - full of news and updates on our companies, product ranges and projects.

DOWNLOAD News Strand - Issue 1

There are a variety of manual and electrical options available for escape door hardware but as with all products, its essential to consider the end user and the environment in which devices are to be placed. The primary purpose of any door on an escape route is for it be readily openable, and the type of premises and its level of occupancy will define whether what type of panic or emergency exit hardware to use.

The Code of Practice: Hardware for Fire and Escape Doors, published by the Door Hardware Federation (DHF) and the Guild of Architectural Ironmongery (GAI) defines the two:

In most cases a mechanical panic device will be the first choice. However, it’s worth considering if the door is to be used for other access requirements and whether users might have accessibility issues. For example, in a hospital or care home, motorised touch bars could provide additional functionality and ease-of-use.

Safety and security will also be a factor. All panic and emergency exit devices provide a level of security against intrusion, but where there is a need for increased security, additional measures can be taken to enhance it without compromising the ability of people to escape during an emergency.

It is essential to liaise with local building and fire authorities to determine building occupancy and undertake risk assessment if such measures are deemed necessary. These can include audible alarms, door monitoring devices and CCTV.

Motorised devices are often used on escape doors which require external access control to restrict who enters a building such as an entrance to a school or college. They are also suitable for use on automatic doors.

Motorised touch bars also provide convenience and enable efficient building management. They can be linked to a variety of access control systems which use swipe card, digital keypad or proximity reader to allow controlled access from outside. They are ideal for large commercial or public buildings and with the addition of a microswitch they can be linked into an estate management off-site control to provide door monitoring.

It is important that any panic exit device is able to operate safely for a realistic lifetime.

BS EN 1125 and BS EN 179 outline testing standards used to verify the durability of products:

All Strand Hardware panic and emergency exit devices have achieved Grade 7 durability standards and are UKCA marked.

They are also supplied with a maintenance log book that should be passed onto the end user. This includes a table to record weekly and monthly checks which should be undertaken to ensure the device is working correctly.

When it comes to emergency and panic devices, Strand Hardware offers the best way out and we have experts on hand to make selection easier.

For further information about Strand Hardware products email:

Want to breathe new life into a stuffy indoor space with cost-effective natural ventilation? The answer could be to keep things simple, according to Strand Hardware, which recommends two key steps to assess requirements and identify the right solution.

Step one requires a bigger picture view: its essential to consider the building’s conditions and orientation – its size, location, positioning and wider environment. This will indicate wind velocity and direction which is needed to optimise air flow and exhaust emissions from inside the premises.

Knowing how the building is to be used, its construction and internal layout (including partitions, doors and chimneys) is also vital, along with window sizing, location, fabric and an understanding of how they function.

Budget is a primary consideration but the beauty of natural ventilation is that it can be achieved without breaking the bank. Manual systems offer the ultimate cost-effective option. Unlike integrated powered systems, they require little by way of capital investment. They are also easier to use and maintain.

Step two of the assessment requires specifics: sufficient detail to identify the products and quantities needed:

Craig Fox, Sales Director for Strand Hardware, said that manual solutions offer a cost effective way of operating windows to provide natural ventilation for new build or existing buildings.

“Strand’s Duoflex range is frequently installed in workplaces, offices, hospitals and educational establishments which benefit from natural ventilation.

“Providing a system that is safe and easy-to-use is essential. Health and safety requirements should be considered so that if windows are at a height, people will not be tempted to over-reach or stand on a chair in order to access them,” he said.

Other products may be used to optimise the solution. Building orientation and its levels of sun, shade and wind direction will determine if they are needed. For example, buildings with double aspects, a large run of windows or large glazed panels, may benefit from reflective film or blinds to prevent the ‘greenhouse effect’.

While those within a densely built environments, such as town centres with tall buildings, or premises with fewer opening windows, may require electrically driven operators, fans/filters to improve air flow and quality.

In just two simple steps, you can say goodbye to stuffy air and hello to comfort and well-being. Get ready to take a deep breath and transform your space into the ultimate sanctuary of freshness and vitality.

For more information visit: www.strandhardware.co.uk/products/window-and-door-hardware/strand-duoflex email:

Strand Hardware has made its mark – completing UKCA compliancy more than a year ahead of the new deadline.

It completed certifications for all its Panic Hardware product ranges – 290 products in total – at the end of last year, in preparation for the original deadline.

The original deadline was intended to be 1 January 2023 but the Government announced an extension as many companies were simply not ready.

The new requirement is compulsory for products which fall within the scope of a ‘harmonised/designated standard’ being made available for sale in the UK. They can continue to be CE marked until 30 June 2025 under a 'presumption of conformity'.

Strand Hardware Operations Director Jo Walls said that she was delighted that Strand was fully prepared and had made the transition ahead of schedule.

“We completed our requirements towards the end of last year. We are ready! and have everything in place for the new deadline and have begun to mark our products with the required UKCA markings. Our Declaration of Performance (DOPs), fitting instructions, labelling and certification have all been completed and the DoPs are available on our website for download.”

For more information contact:

Strand Hardware defied the ‘Beast from the East’ when it went ahead with its office reopening event and rededication ceremony yesterday (Thursday 9 March).

Fortunately, most guests were not deterred by the snowfall, with 70 people in attendance, including staff, suppliers, customers and media.

This included representatives from Athmer, who travelled from Germany, to support its UK distributor and Simon Forrester, Chief Executive Officer of the Guild of Architectural Ironmongers. They toured the newly refurbished Strand House, in Walsall, where the company has been located for more than 30 years.

Christine Franks, the wife of company founder, the late Jonathan Franks, carried out the ribbon cutting ceremony.

“I know that Jonathan would have been extremely proud to see how Strand Hardware has flourished,” she said.

The building has had a radical make over resulting in a more modern, open plan work space for its expanding team. It also includes a hi-tech reception and energy efficient measures including better insulation and motion sensor lighting.

Many of the materials used in the project were sourced from suppliers and clients including new windows, fire doors, electricals, plumbing, furniture, decoration, carpeting and signage, along with some of its own ironmongery products.

Guests were treated to refreshments and goody bags and a special cake was created to mark the event.

Managing Director Steve Marshall said: “The completion of the refurbishment project has taken many months of planning, organisation, disruption and hard work from all concerned. Those who had visited us before will no doubt see a vast improvement in our working environment, and our environmental credentials.

“Since the dear late Mr Jonathan Franks set up the company in 1992, Strand Hardware has gone from strength-to-strength, navigating its way through many national and global challenges, while always sitting solidly on its impeccable financial foundations.”

He also paid tribute to Strand’s ‘family’ – its 21-strong workforce and Jonathan’s daughter, Catherine Franks who took over as MD in 2005 and now Chairs its board.

“She has positioned Strand as one of the market leaders in our industry with customer service levels that are second to none and a reputation of which we can be proud,” he added.

Strand Hardware has given its company headquarters a radical make over – improving its energy efficiency, work space and creating a welcoming new hi-tech reception.

It has used products from many of its suppliers and customers for the project including new windows, fire doors, electricals, plumbing, furniture, decoration, carpeting and signage, along with some of its own ironmongery products.

The refurb in the second change project to take place at Strand Hardware in recent months and follows a review and upgrade of its warehousing processes undertaken with WMG (Warwick Manufacturing Group).

It has resulted in a more modern, open plan work space for its expanding team – encouraging greater team synergy and literally breaking down walls to silo working which had been enforced by the old layout.

Strand has occupied the premises on the Premier Business Park, in Walsall, since the company was founded more than 30 years ago and according to Managing Director Steve Marshall a little modernisation has been beneficial.

“Although Strand’s offices were perfectly functional, they were looking a little dated and our work with WMG gave us the impetus to extend our programme of improvements. Not only will it enhance working conditions for the Strand Hardware team but also convey a better image of who we are and what we are about to visiting business associates.

“Efficiency has underpinned all our recent changes. This includes energy efficiency and eco-saving measures such as the introduction of natural ventilation, insulation and energy-saving devices,” he said.

Shared facilities including board room, kitchen and bathrooms have been included in the make-over and equipment upgraded. Staff have also benefitted from ergonomically designed furniture and layout.

Its reception has been reconfigured to make it lighter and more airy. It also features digital displays to welcome visitors and showcase Strand’s extensive product range.

A key driver in the process has been digitisation – reducing paper-based processes and transferring its traditional filing system to a cloud based environment.

The company is planning an open day for company contacts and has invited Mayor of Walsall to oversee a rededication ceremony.

Strand Hardware has developed leaner assembly, dispatch and warehousing processes – saving hundreds of staff hours each year – in a joint project with a crack team from Warwick University.

The project with WMG (Warwick Manufacturing Group) has optimised warehouse layout and movement for the efficient flow of picking, assembly and packing operations across key ranges.

It involved measuring processes via time study and motion analysis through site visits, video capture and process flow assessment. Findings outlined cycle times and mapped the movement of people.

The resulting report outlined a series of recommendations to improve process capacity, including quick wins and minor modifications to warehouse and workstations layout to introduce time savings.

This has led to the introduction of mobile Kanban shelving within the assembly area to allow components to be picked and assembled more efficiently. The double-sided racks allow bins to be restocked by a dedicated person who conveys stock between Strand’s warehouse and its head office on another part of the site.

Steve Marshall, Managing Director of Strand Hardware, said that the project had been “thorough and exacting”.

“Strand Hardware has grown over 30 years. Like most companies, while scaling up, we have focused on customer requirements and day-to-day business operations. We felt that the time had come to review what we were doing and whether we could be doing it more efficiently, which led to the opportunity to work with WMG.

“Having experts come into the business with fresh pairs of eyes, ask the right questions and with the knowledge to assess and analyse our operations has been invaluable. It was important for us not to disrupt warehouse activity, so recommendations had to incorporate improvements that would be easy to apply. In the long term, this will make our business leaner and more efficient – the ideal foundation for future growth,” he said.

The project was undertaken with funding from the Digital Innovation for Manufacturing programme.

Strand Warehouse and Production Manager Andy Michel said that it had been fascinating to work with the University Team: “The results will make the job easier for many of the team and help Strand Hardware in its continuous improvement.”

Chris Wang, of WMG SME Group added: “WMG and Strand Hardware have worked collaboratively to analyse their current assembly area in readiness for optimising their production facility. Across the three recommendations put forward, a maximum 50% reduction in cycle times per unit has been predicted which allows for a 5.105% capacity increase.”

Strand Hardware is taking the panic out of buying emergency exit solutions by outlining key considerations for specification. It urges customers to put ‘safety first’ – prioritising functionality, quality, and performance at the head of decision-making.

CE marked products for fire and escape doors are a must for architects and specifiers and best practice determines that products comply with Construction Product Regulations.

Strand Hardware’s Antipanic Emergency Exit and Panic range meet these requirements. In an emergency or panic situation, they release exit doors by means of a push bar, touch bar or a push pad on outward opening single or double doors.

For day-to-day use, doors can be opened from the outside with an outside access device.

“When an emergency door can be locked or opened from the outside, it should still be freely released from inside – maintaining security without compromising its basic panic function,” said Strand Hardware MD Steve Marshall.

He urges specifiers to identify suitable solutions by considering:

Strand Hardware offers PH (modular push bar/push pad range), PHT (touch bar range), PHTM (motorised touch bar range) options. Selection criteria is provided by the EN standards EN1125 and EN179 and should reflect occupancy levels. Other matters to be considered include creating clear opening requirements, how the door is intended to be used, whether it is fire resisting, the operating environment etc. Aesthetics and budget will also have a place, but these are secondary to the life safety aspect.

Different strikes are used to suit various door materials and construction. For PVCU doors and frames, a range of profile related strikes are available for which the system manufacturer and profile model is needed. Glass doors require patch fittings to suit the escape device and door construction. Whether the doors are fire-resisting and how the door is hung will also have a bearing.

Single and three-point locking latches are available across all the ranges with the ability to convert on site from three point to two point in the most cases. Factors to be considered include whether the door is single or double, construction, material and size. For double doors requiring escape through both leaves, it is critical that whichever door leaf is operated it must open and whether the doors are rebated through the lock stile section/overlapping plates or are plain edged.

External access can be provided by a mechanical outside access device, using a key, push button digital combination and in most cases either a lever handle or knob. Again, thought needs to be given to how the door is to be used. Most electronic access control can be accommodated by use of an internal motorised touch bar.

Door widths and heights should be checked before ordering as many wider and taller doors can be catered for from stock by use of wider crossbars, wider model touch bars and extra-long rod kits.

Powder coated white and black finishes are available from stock along with the standard silver grey, which have the option of a green cross bar. A decorative plated satin stainless steel finish and simulated polished brass are available for many ranges. Where a high degree of corrosion resistance is necessary the DFine grade 316 stainless steel is available. Many other finishes can be provided to special order.

For more information on Strand Hardware’s emergency exit and panic hardware range contact:

We sell our products through selected wholesalers and architectural ironmongers. We have experts on hand to help architects and end users with product information but orders would need to be placed with our distributors and they will also give pricing information. If you aren't sure where to buy we can provide details of nearest distributor.

Our catalogues and fitting instructions can all be downloaded here. If there is something you cannot find please let us know and we will be happy to email it to you.

For details of your nearest distributor or for further information on any of our products please contact us by phone or email.

We supply high quality Window and Door Hardware for commercial buildings as well as our range of locally manufactured products; we are sole UK distributors for top European manufacturers such as Athmer Automatic Door Seals and Antipanic Panic Hardware. We have built our reputation by delivering first class customer service and technical support which is provided through our experienced industry professionals.

Stay up to date with the latest happenings at Strand Hardware.

Strand Hardware Limited

Strand House

Premier Business Park

Long Street

Walsall

WS2 9DY

UK

Tel: (+44) 1922 639111

Email: info@strandhardware.co.uk

© 2020 Strand Hardware Ltd.

Website Design by Make it Seen Media